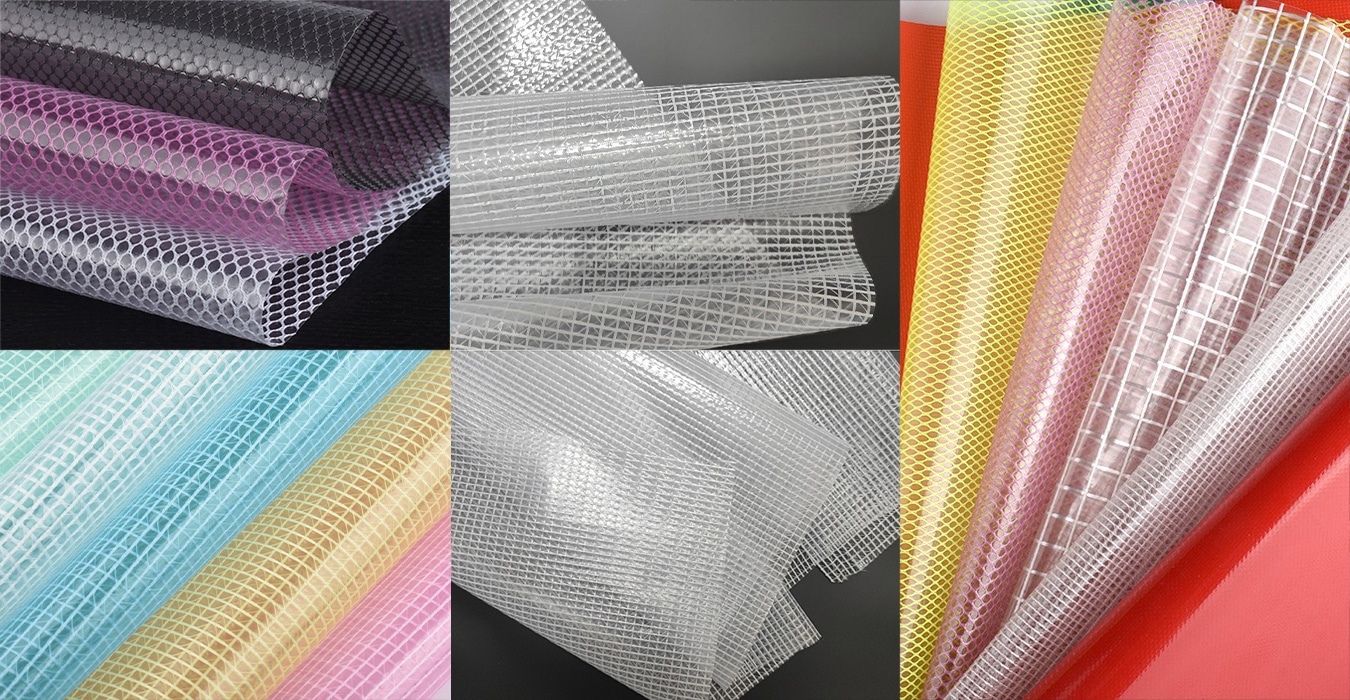

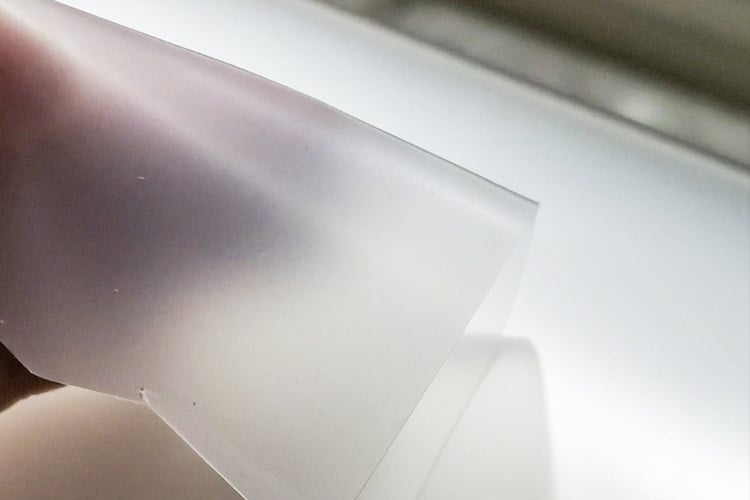

Flexible PVC is a soft, flexible material that ranges in appearance from transparent to opaque. PVC is manufactured with plasticizers, which confer rubbery properties on the end product. By adjusting the type and amount of plasticizers, plastic molders can achieve a large range of flexible compositions. Common applications in which Flexible PVC is used include:

- Wire & Cable Jacketing

- Pool Liners

- Flooring

- Garden Hoses

- Rainwear & Boots

- Medical Tubing

- Automotive Interior Trim

- Plumbing

- Electrical Cable Insulation

- Inflatable Products

- Imitation leather

- Signage

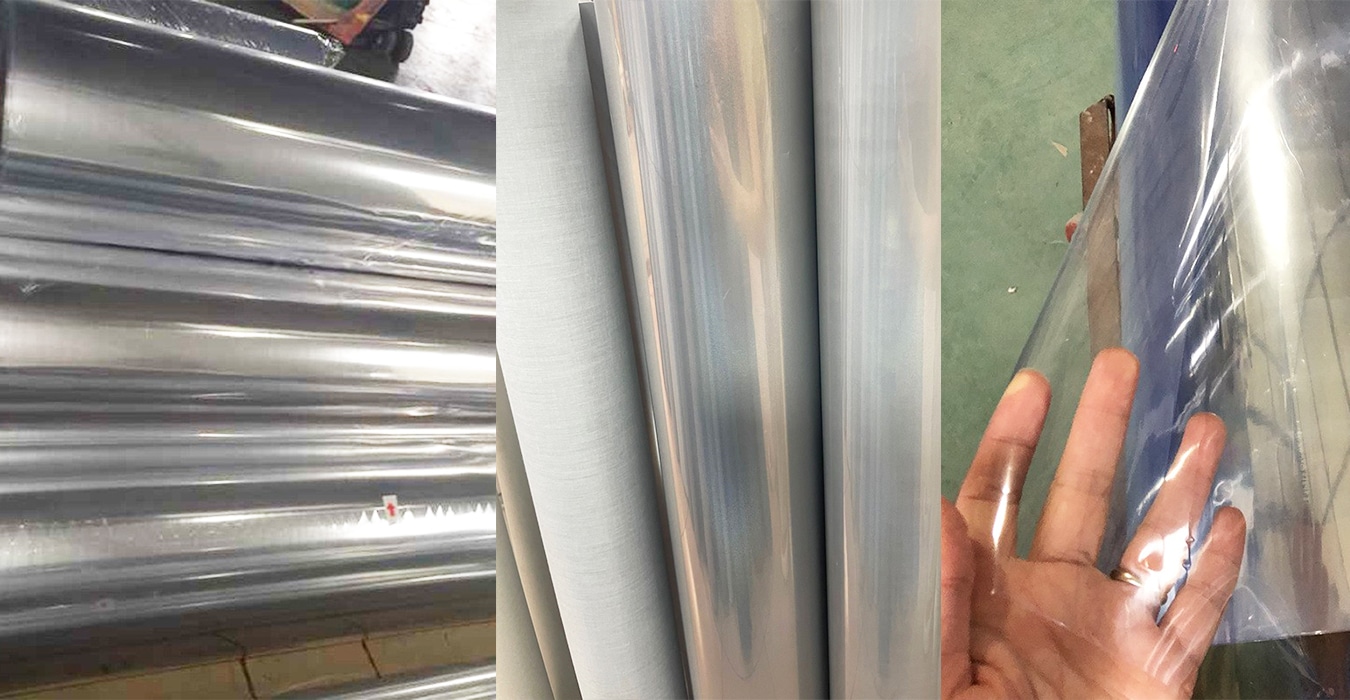

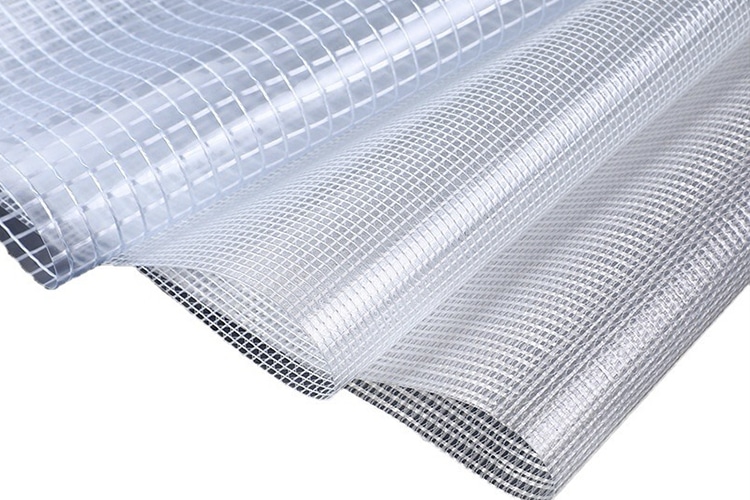

It has been several years that a soft transparent polyvinyl chloride (PVC) plastic sheet, commonly known as “soft glass”, or “crystal plate” in China and other developing countries, has quietly and gradually found extensive applications in household and public place. This material has widely replaced cloth and glass as table cover in household and office, and replaced cloth as door drape in public place in China.

Flexible soft PVC offers a number of advantages, such as:

- Low Cost

- Good Strength

- High Clarity

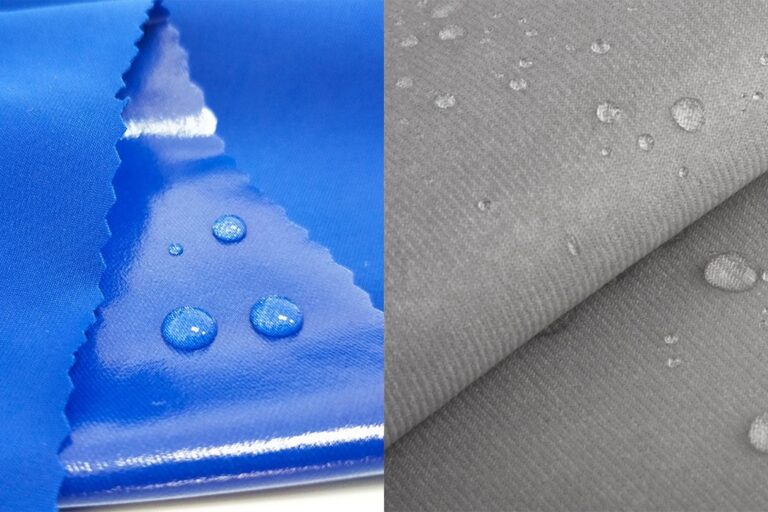

- Good Outdoor Weathering Characteristics

- Good Tear Strength and Kink Resistance

- Good Compression Set Values

Disadvantages:

- Poor Thermal Capability

- Sensitive to UV Degradation

- Sensitive to Oxidative Degradation

Applications