![3454 [转换]_复制](https://uoosport.com/wp-content/uploads/2019/03/Neoprene-Fabric-Laminated-Details.jpg)

Neoprene Sheet Size & Thickness

| Valid Size | 120*210CM, 130*330CM, 140*340CM, 145*345CM, 130*660CM, Other Foam Roll: 120-150*5000CM/Roll |

|---|---|

| Thickness | 0.5MM – 30MM |

Neoprene Foam Color

| Neoprene Type | SBR | SCR | CR | RPET Recycle SBR | YULEX | EVA Foam/Polyurethane Foam | Natural Foam Rubber |

|---|---|---|---|---|---|---|---|

| Foam Color | Black, Beige, Water White, White | Black, Beige | Black, Beige | Black, Beige | Black | Black, Beige, White, Water or Other Colors | Black or OEM color with large quantity or Latex |

ECO-Neoprene Foam Can Fulfill The Below International Standards

| REACH | Two hundred and eleven (211) substances in the Candidate List of Substances of Ver High Conern (SVHC) for authorization published by European Chemicals Agency (ECHA) on and before Jan 19, 2021 regarding Regulation (EC) No 1907/2006 concerning the REACH. |

|---|---|

| RoHs | Restriction of Hazardous Substances – RoHS 2.0 Directive 2011/65/EU Annex II ; Recasting 2002/95/EC |

| GRS | Recycle PET Certificate If Needed |

| Toxic Elements | Migration of Certain Elements – EN 71-3:1994+A1:2000+AC:2002 |

Neoprene Fabric Factory

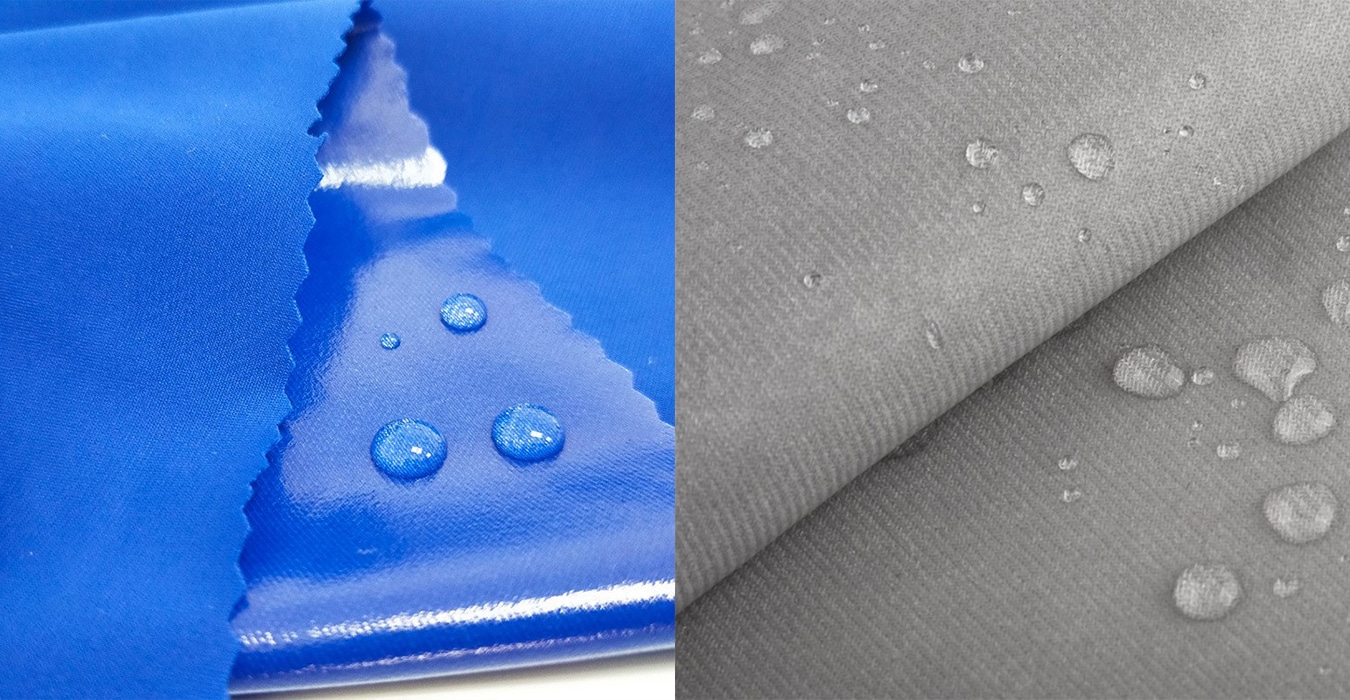

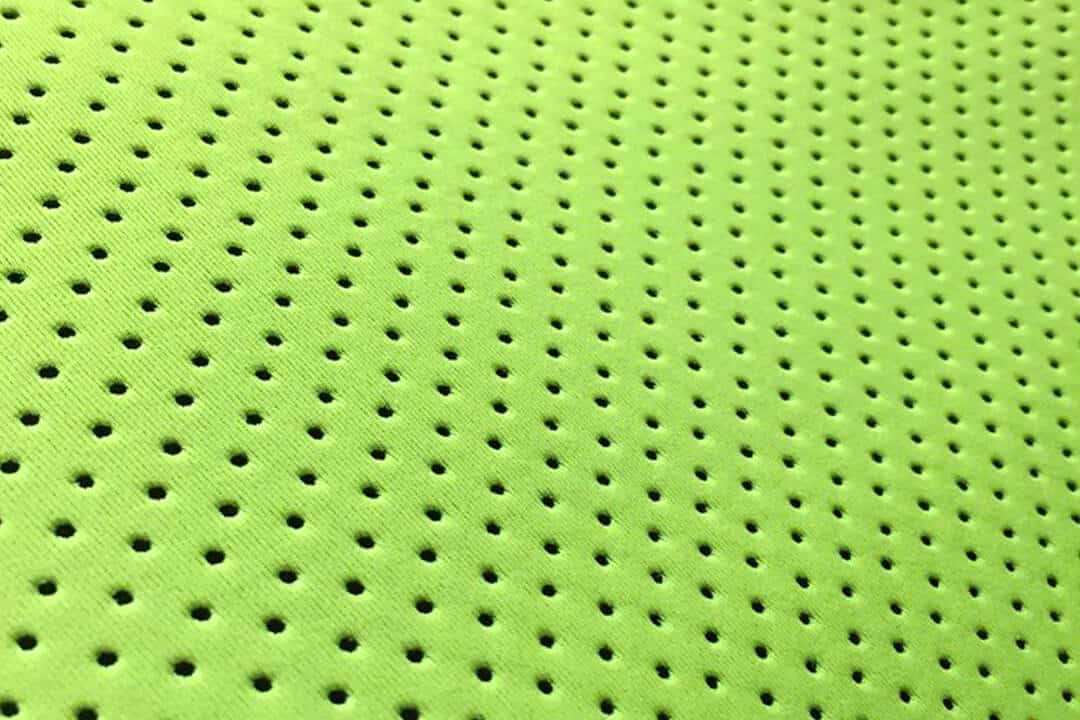

“Neoprene Fabric” is made of “Neoprene Foam” (foamed elastomer in closed cell form). The “Neoprene Foam” is the middle layer, and the surface is usually “Laminate” the fabric, or “Smooth Skin” or “Coating”. Some products also use the “Embossing” and “Perforation” processes. The main features are waterproof, warm, and have excellent cushioning protection. And also be breathable processing for customer needs. “Neoprene Fabric” was originally used mainly for wetsuits, so it is also called “Wetsuit Fabric” or “Wetsuit Material”, and now we also use it extensively to make other products.

Neoprene Fabric Manufacturer

We are a professional neoprene factory, using different kinds of neoprene foams and fabrics from different countries or regions, according to customers’ different requirements, we can combine them into different grades and types of “Neoprene Fabric”. We can provide a combination of high grade materials such as CR neoprene foam + elastic fabric, and also provide a combination of low grade materials such as SBR neoprene foam + polyester fabric, all depending on the positioning and budget of the customers’ products. The price difference between different types of neoprene foams and fabrics is very large (the price ratio of CR, SCR and SBR foams is about 4 : 2 : 1), and we promise to always provide a veritable product.